Introduction

Modern outdoor infrastructure demands sophisticated drainage solutions that seamlessly integrate functionality with aesthetic appeal. The Customized Hidden Linear Drainage 304 Stainless Steel Curved Channel Floor Drain for Outdoor Park with Anti-corrosion Properties represents a breakthrough in contemporary drainage technology, specifically engineered for challenging outdoor environments. This advanced drainage system combines superior materials engineering with innovative design principles to deliver exceptional performance in parks, recreational areas, and various outdoor installations where traditional drainage solutions fall short.

As urban planning evolves to prioritize both functionality and visual harmony, hidden linear drainage systems have emerged as the preferred choice for architects, landscape designers, and facility managers seeking unobtrusive yet highly effective water management solutions. The curved channel design of this specialized floor drain addresses the unique challenges posed by outdoor environments while maintaining the sleek, minimalist appearance that modern park designs demand.

Product Overview

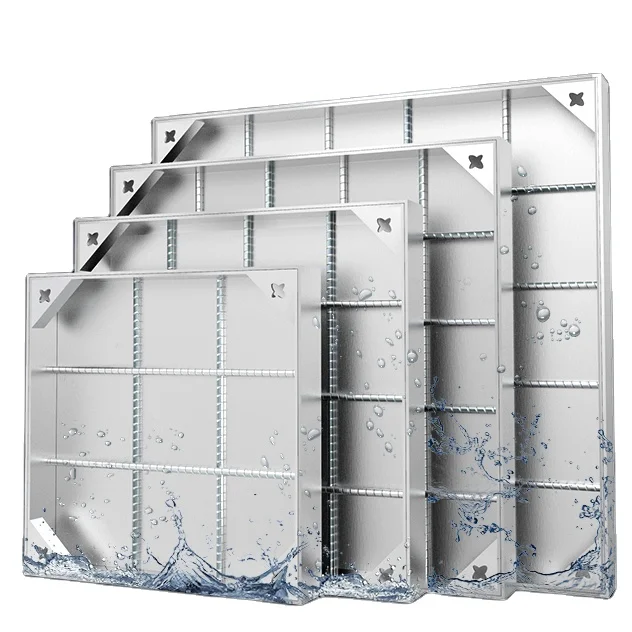

This premium stainless steel drainage solution represents the convergence of advanced metallurgy and thoughtful engineering design. Constructed from high-grade stainless steel material, the system provides exceptional resistance to environmental stressors while maintaining structural integrity across diverse weather conditions. The curved channel configuration optimizes water flow dynamics, ensuring efficient drainage performance even during heavy precipitation events that are common in outdoor park environments.

The hidden linear design philosophy eliminates the visual disruption typically associated with traditional drainage infrastructure. By incorporating the drainage channel seamlessly into the surrounding surface materials, this system preserves the aesthetic continuity of park walkways, plazas, and recreational areas. The anti-corrosion properties inherent in the stainless steel construction ensure long-term performance reliability, reducing maintenance requirements and extending the operational lifespan significantly beyond conventional drainage alternatives.

Advanced manufacturing techniques enable precise customization of channel dimensions, curvature specifications, and surface finishes to accommodate diverse installation requirements. This flexibility makes the system particularly valuable for complex outdoor projects where standard drainage solutions cannot adequately address site-specific challenges or design constraints.

Features & Benefits

Superior Material Engineering

The foundation of this drainage system lies in its carefully selected stainless steel composition, which provides exceptional resistance to corrosion, oxidation, and chemical degradation. Unlike traditional drainage materials that deteriorate rapidly in outdoor environments, this specialized alloy maintains its structural properties and surface integrity throughout extended exposure to moisture, temperature fluctuations, and various environmental contaminants commonly encountered in park settings.

The material's inherent antibacterial properties contribute to improved hygiene standards in public outdoor spaces, while its non-porous surface prevents the accumulation of organic debris that can compromise drainage efficiency over time. This self-cleaning characteristic significantly reduces maintenance requirements and ensures consistent performance throughout the system's operational lifetime.

Innovative Curved Channel Design

The curved channel geometry represents a significant advancement in linear drainage technology, optimizing hydraulic flow characteristics to maximize water evacuation efficiency. This design feature prevents standing water accumulation and reduces the risk of blockages that commonly plague traditional straight-channel systems. The smooth, continuous curves guide water flow naturally, minimizing turbulence and ensuring rapid drainage even during peak flow conditions.

The hidden linear configuration seamlessly integrates with surrounding surfaces, creating an virtually invisible drainage solution that preserves the visual integrity of outdoor spaces. This design approach is particularly valuable in high-profile park installations where aesthetic considerations are paramount, allowing designers to implement effective drainage without compromising the intended visual experience.

Enhanced Anti-Corrosion Properties

Beyond the inherent corrosion resistance of the stainless steel base material, this drainage system incorporates additional protective treatments that further enhance its durability in challenging outdoor environments. These specialized coatings provide an extra barrier against salt exposure, acid rain, and other corrosive elements that can compromise lesser drainage systems over time.

The anti-corrosion properties extend to all system components, including fasteners, grates, and connection elements, ensuring uniform protection throughout the entire installation. This comprehensive approach to corrosion prevention translates to significantly reduced lifecycle costs and minimal maintenance interventions, making it an economically attractive solution for long-term outdoor installations.

Applications & Use Cases

The versatility of the Customized Hidden Linear Drainage 304 Stainless Steel Curved Channel Floor Drain for Outdoor Park with Anti-corrosion Properties makes it suitable for a diverse range of outdoor applications where effective water management is essential. Public parks and recreational facilities represent the primary application domain, where the system's ability to handle high foot traffic while maintaining aesthetic appeal is particularly valuable.

Urban plazas and pedestrian walkways benefit significantly from the hidden linear design, which eliminates trip hazards while providing superior drainage capacity. The curved channel configuration is especially effective in areas with complex topography or where drainage patterns must accommodate existing landscape features. Shopping centers, airports, and transportation hubs with outdoor components frequently specify this drainage solution for its combination of performance reliability and visual discretion.

Residential and commercial landscaping projects increasingly incorporate this drainage technology where traditional solutions would detract from carefully planned outdoor environments. Pool decks, patios, and outdoor entertainment areas particularly benefit from the system's ability to handle water efficiently while maintaining clean, uninterrupted surface appearances. The customization capabilities allow architects and designers to integrate drainage seamlessly into even the most sophisticated outdoor design concepts.

Sports facilities and recreational complexes represent another significant application area, where the drainage system's durability and performance consistency are essential for maintaining safe playing conditions. Tennis courts, basketball courts, and walking tracks require reliable drainage that can handle both regular precipitation and cleaning operations without creating surface irregularities or safety concerns.

Quality Control & Compliance

Rigorous quality assurance protocols govern every aspect of the manufacturing process, ensuring that each drainage system meets the exacting standards required for demanding outdoor applications. Advanced testing procedures validate material properties, dimensional accuracy, and performance characteristics before products are approved for shipment to international markets.

Environmental testing simulates the extreme conditions commonly encountered in outdoor park installations, including freeze-thaw cycles, thermal expansion stress, and prolonged moisture exposure. These comprehensive evaluations ensure that the drainage systems will perform reliably throughout their intended service life, regardless of regional climate variations or seasonal weather patterns.

International compliance standards guide the development and manufacturing processes, ensuring compatibility with global building codes and safety regulations. This commitment to regulatory compliance simplifies the specification process for international projects and provides confidence that installations will meet local requirements across diverse markets.

Continuous improvement initiatives incorporate feedback from field installations to refine manufacturing processes and enhance product performance. This ongoing commitment to quality excellence has established the drainage system as a trusted solution among architects, contractors, and facility managers worldwide who require reliable performance in challenging outdoor environments.

Customization & Branding Options

Comprehensive customization capabilities enable the adaptation of drainage systems to meet specific project requirements and design preferences. Channel dimensions, curvature profiles, and surface treatments can be modified to accommodate unique installation constraints or aesthetic objectives. This flexibility is particularly valuable for high-profile projects where standard configurations may not adequately address site-specific challenges.

Surface finishing options range from brushed and polished treatments to specialized coatings that enhance slip resistance or provide specific aesthetic effects. Color matching capabilities allow the drainage components to blend seamlessly with surrounding materials, further enhancing the hidden linear design concept. Custom perforation patterns and grate designs can be developed to meet specific hydraulic requirements or architectural preferences.

Private labeling and branding services support distributors and contractors who wish to offer differentiated products in their respective markets. Custom packaging and documentation can incorporate specific branding elements while maintaining the high-quality presentation standards that reflect the premium nature of the drainage solution.

Engineering support services assist customers in developing optimal configurations for complex installations, ensuring that customized solutions maintain the performance characteristics and reliability standards of standard products. This collaborative approach has proven invaluable for landmark projects where conventional drainage approaches were inadequate.

Packaging & Logistics Support

Professional packaging solutions protect drainage components during international shipping while minimizing transportation costs through efficient space utilization. Specialized protective materials and custom-designed packaging configurations ensure that products arrive in perfect condition, regardless of shipping duration or handling conditions encountered during transit.

Comprehensive documentation packages include detailed installation instructions, technical specifications, and maintenance guidelines translated into multiple languages to support international markets. Digital resources provide additional support materials, including installation videos and troubleshooting guides that facilitate successful project completion.

Flexible shipping arrangements accommodate diverse project timelines and logistical requirements, with options ranging from consolidated shipments for large projects to expedited delivery for urgent requirements. Tracking and communication systems keep customers informed throughout the shipping process, enabling effective project planning and coordination.

Regional distribution partnerships provide local inventory and support services in key markets, reducing delivery times and simplifying the procurement process for routine orders. These partnerships also facilitate warranty service and technical support, ensuring that customers receive prompt assistance when needed.

Why Choose Us

Our company has established a strong presence in international markets through decades of experience developing specialized drainage solutions for challenging outdoor applications. This extensive background has created deep expertise in understanding the unique requirements of diverse climates, installation conditions, and regulatory environments that characterize global markets.

Collaboration with architects, engineers, and contractors worldwide has refined our understanding of evolving design trends and performance requirements in the outdoor infrastructure sector. This market insight enables continuous innovation in product development and ensures that our solutions remain at the forefront of industry advancement.

As a recognized metal packaging manufacturer and custom drainage solutions provider, we maintain comprehensive manufacturing capabilities that support both standard products and highly specialized custom configurations. Our integrated approach to design, manufacturing, and quality control ensures consistent excellence across all products while maintaining the flexibility required for unique project requirements.

Technical support services provide ongoing assistance throughout the project lifecycle, from initial specification development through installation completion and beyond. This commitment to customer success has established long-term partnerships with leading distributors and contractors who rely on our expertise to deliver successful outcomes for their most demanding projects.

Conclusion

The Customized Hidden Linear Drainage 304 Stainless Steel Curved Channel Floor Drain for Outdoor Park with Anti-corrosion Properties represents the ideal convergence of advanced materials engineering, innovative design principles, and practical functionality for demanding outdoor applications. Its superior construction quality, comprehensive customization options, and proven performance reliability make it the preferred choice for architects, contractors, and facility managers seeking drainage solutions that excel in both performance and aesthetic integration. The combination of hidden linear design, exceptional anti-corrosion properties, and curved channel efficiency creates a drainage system that not only meets the functional requirements of modern outdoor spaces but enhances their overall design quality and long-term value.