Introduction

Modern commercial and residential environments demand robust drainage solutions that combine exceptional durability with aesthetic appeal. The demand for high-performance floor grilles has intensified as architects, contractors, and facility managers seek reliable drainage covers that withstand heavy foot traffic while maintaining elegant functionality. Our Customized High-load-bearing Capacity Floor Grilles Are Used for Kitchen Sidewalk Drainage Covers and Metal Strip Grilles represent the pinnacle of engineered drainage technology, delivering uncompromising strength and versatility across diverse applications.

These premium drainage solutions address critical infrastructure needs in commercial kitchens, pedestrian walkways, industrial facilities, and residential spaces where conventional grilles fail to meet demanding performance standards. Through advanced metallurgy and precision manufacturing techniques, these floor grilles establish new benchmarks for load-bearing capacity while ensuring optimal water flow management and long-term structural integrity.

Product Overview

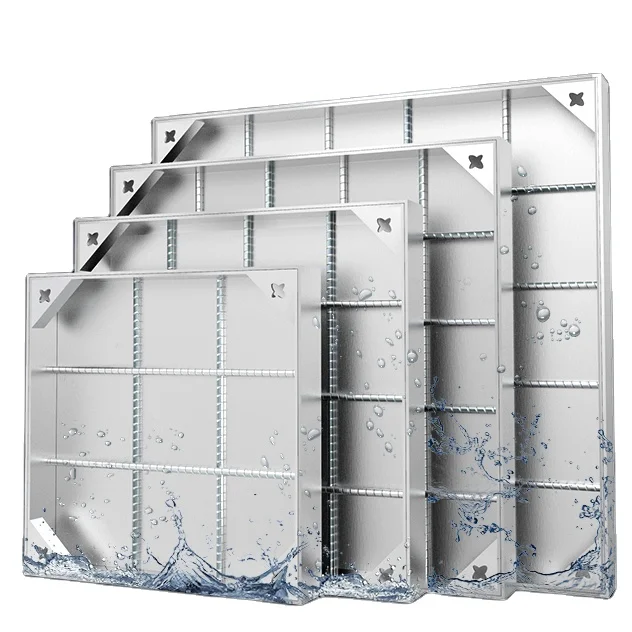

Our heavy-duty floor grilles exemplify superior engineering excellence through their innovative metal strip construction and reinforced framework design. Each unit features meticulously crafted drainage openings that maximize water flow efficiency while preventing debris accumulation and clogging issues. The integrated metal strip configuration ensures uniform load distribution across the entire surface area, enabling these grilles to support substantial weight loads without compromising structural stability or drainage performance.

The sophisticated manufacturing process incorporates advanced welding techniques and precision machining to create seamless joints and smooth surface finishes. These Customized High-load-bearing Capacity Floor Grilles Are Used for Kitchen Sidewalk Drainage Covers and Metal Strip Grilles undergo rigorous quality testing to verify their exceptional strength characteristics and corrosion resistance properties. The result is a premium drainage solution that delivers reliable performance across challenging environmental conditions while maintaining aesthetic appeal and functional excellence.

Features & Benefits

Superior Load-Bearing Performance

The exceptional load-bearing capabilities of these floor grilles stem from their advanced structural engineering and high-grade material composition. The reinforced metal strip design distributes weight evenly across multiple support points, preventing localized stress concentrations that could compromise structural integrity. This innovative approach enables the grilles to support heavy equipment, frequent pedestrian traffic, and substantial static loads while maintaining dimensional stability and drainage efficiency.

Enhanced Corrosion Resistance

Premium surface treatments and corrosion-resistant alloys ensure these drainage covers maintain their structural properties and aesthetic appearance despite exposure to harsh environmental conditions. The protective coating systems resist chemical degradation, moisture penetration, and oxidative damage, extending service life significantly compared to conventional drainage solutions. This enhanced durability reduces maintenance requirements and replacement costs while ensuring consistent performance across extended operational periods.

Optimized Drainage Efficiency

The precisely engineered opening patterns and metal strip configurations maximize water flow rates while preventing debris accumulation and blockage issues. Strategic spacing between drainage elements ensures rapid water evacuation during peak flow conditions while maintaining structural support integrity. This optimized design minimizes standing water risks and reduces maintenance requirements associated with cleaning and debris removal activities.

Applications & Use Cases

Commercial kitchen environments represent primary applications for these Customized High-load-bearing Capacity Floor Grilles Are Used for Kitchen Sidewalk Drainage Covers and Metal Strip Grilles, where they provide essential drainage functionality while withstanding heavy equipment loads and frequent cleaning procedures. Restaurant kitchens, institutional food service facilities, and industrial food processing operations rely on these grilles to maintain sanitary conditions and prevent water accumulation that could compromise safety and hygiene standards.

Pedestrian walkways and sidewalk applications benefit from the exceptional durability and aesthetic appeal of these metal strip grilles. Urban planners and municipal authorities specify these drainage covers for high-traffic areas where conventional solutions fail to provide adequate longevity and performance. The robust construction withstands constant foot traffic, weather exposure, and mechanical stress while maintaining smooth surfaces that ensure pedestrian safety and comfort.

Industrial facilities and manufacturing environments utilize these heavy-duty grilles for process water management, equipment drainage, and facility maintenance applications. The superior load-bearing characteristics accommodate heavy machinery, material handling equipment, and substantial static loads while ensuring reliable drainage performance. Chemical processing facilities, automotive manufacturing plants, and heavy industry operations depend on these grilles to maintain operational efficiency and environmental compliance standards.

Quality Control & Compliance

Comprehensive quality assurance protocols ensure every floor grille meets stringent performance standards and regulatory requirements. Advanced testing procedures verify load-bearing capacities, drainage efficiency, corrosion resistance, and dimensional accuracy throughout the manufacturing process. These rigorous quality controls guarantee consistent product performance and reliability across diverse application environments and operational conditions.

International compliance standards guide material selection, manufacturing processes, and performance verification procedures. The drainage covers conform to relevant building codes, safety regulations, and environmental standards applicable to commercial and industrial installations. This comprehensive compliance approach ensures seamless integration into diverse projects while meeting local regulatory requirements and industry best practices.

Traceability systems document material origins, manufacturing parameters, and quality test results for every production batch. This detailed documentation supports warranty claims, performance verification, and regulatory compliance requirements while enabling continuous improvement initiatives. The systematic approach to quality management demonstrates our commitment to delivering superior drainage solutions that exceed customer expectations and industry standards.

Customization & Branding Options

Extensive customization capabilities accommodate specific project requirements and aesthetic preferences through flexible design modifications and material selections. Custom dimensions, opening patterns, surface finishes, and mounting configurations enable seamless integration into diverse architectural and engineering applications. This design flexibility ensures optimal performance while maintaining visual harmony with surrounding environments and structural elements.

Advanced manufacturing technologies support complex geometric configurations and specialized surface treatments that enhance functionality and aesthetic appeal. Custom logos, text markings, and decorative elements can be incorporated into the grille design through precision machining and specialized coating processes. These branding opportunities enable facility identification, wayfinding assistance, and corporate identity integration while maintaining structural performance and drainage efficiency.

Material selection options include various alloy compositions, surface treatments, and protective coatings that address specific environmental conditions and performance requirements. Specialized applications may require enhanced chemical resistance, elevated temperature tolerance, or specific electrical properties that can be achieved through targeted material modifications and surface engineering techniques. This comprehensive customization approach ensures optimal performance across diverse operational environments and application scenarios.

Packaging & Logistics Support

Sophisticated packaging systems protect these precision-engineered drainage covers during transportation and storage while minimizing handling damage and corrosion risks. Custom protective materials and secure mounting systems ensure products arrive in pristine condition regardless of shipping distances or environmental conditions encountered during transit. The packaging design optimizes space utilization while providing adequate protection against mechanical damage and moisture exposure.

Comprehensive logistics coordination supports global distribution requirements through established shipping networks and customs clearance procedures. Experienced logistics teams manage complex international shipments while ensuring compliance with import regulations and documentation requirements. This streamlined approach minimizes delivery delays and reduces administrative complexity for international customers and distribution partners.

Inventory management systems maintain optimal stock levels while supporting rapid fulfillment of standard and custom orders. Strategic warehouse locations enable efficient distribution across multiple geographic regions while reducing transportation costs and delivery timeframes. Advanced planning systems coordinate production schedules with customer delivery requirements to ensure timely project completion and installation schedules.

Why Choose Us

Our company brings extensive experience in precision metal fabrication and drainage system engineering to every project, having served diverse industries across international markets for over two decades. This deep expertise enables us to deliver innovative solutions that exceed performance expectations while addressing complex technical challenges and regulatory requirements. Our global presence and multi-industry collaboration have established us as a trusted partner for critical infrastructure projects worldwide.

As a leading metal packaging manufacturer and custom solutions provider, we leverage advanced manufacturing technologies and quality management systems to ensure consistent product excellence. Our comprehensive capabilities extend beyond standard drainage covers to include specialized OEM solutions and custom engineering services that address unique project requirements. This versatility positions us as a preferred supplier for architects, contractors, and facility managers seeking reliable performance and exceptional value.

Continuous innovation drives our product development initiatives, resulting in enhanced performance characteristics and expanded application capabilities. Research and development investments focus on emerging materials, advanced manufacturing techniques, and sustainable design principles that deliver superior environmental performance. Our commitment to technological advancement ensures customers receive cutting-edge solutions that provide competitive advantages and long-term value across diverse applications and operational environments.

Conclusion

The Customized High-load-bearing Capacity Floor Grilles Are Used for Kitchen Sidewalk Drainage Covers and Metal Strip Grilles represent the optimal fusion of engineering excellence, manufacturing precision, and application versatility. These premium drainage solutions deliver exceptional performance across demanding commercial, industrial, and residential applications while maintaining aesthetic appeal and long-term reliability. Through superior load-bearing capabilities, enhanced corrosion resistance, and optimized drainage efficiency, these floor grilles establish new industry standards for quality and performance. The comprehensive customization options, rigorous quality controls, and global logistics support ensure seamless integration into diverse projects while exceeding customer expectations for durability, functionality, and value. This commitment to excellence positions these drainage covers as the preferred choice for discerning professionals who demand uncompromising quality and reliable performance from their infrastructure investments.