Introduction

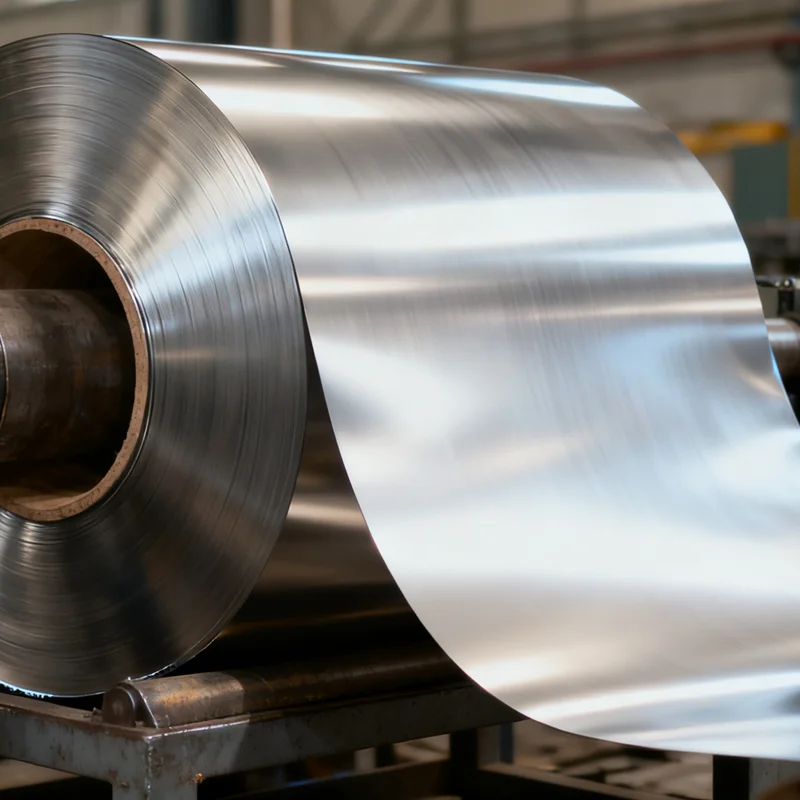

In today's competitive industrial landscape, sourcing high-quality stainless steel materials has become crucial for manufacturers across diverse sectors. The Customized Stainless Steel Coils 201/304L/316/316L Stainless Steel Coils, Cold-rolled 0.5mm and 1.0mm Stainless Steel Coils represent a premium solution designed to meet the exacting demands of modern manufacturing processes. These precision-engineered coils deliver exceptional performance characteristics while maintaining the flexibility necessary for custom applications across multiple industries.

Stainless steel coils serve as the foundation for countless manufacturing applications, from architectural elements to precision components in the automotive and aerospace industries. The cold-rolling process employed in creating these coils ensures superior surface finish, dimensional accuracy, and mechanical properties that exceed industry standards. Whether you're a distributor seeking reliable supply chains or a manufacturer requiring consistent material quality, these customized stainless steel coils provide the versatility and performance needed to achieve your production objectives.

Product Overview

Our comprehensive range of Customized Stainless Steel Coils 201/304L/316/316L Stainless Steel Coils, Cold-rolled 0.5mm and 1.0mm Stainless Steel Coils encompasses multiple grades to address varying application requirements and environmental conditions. The selection includes austenitic stainless steel grades that offer distinct advantages in corrosion resistance, formability, and mechanical strength. Each grade has been specifically chosen to provide optimal performance in its intended application environment.

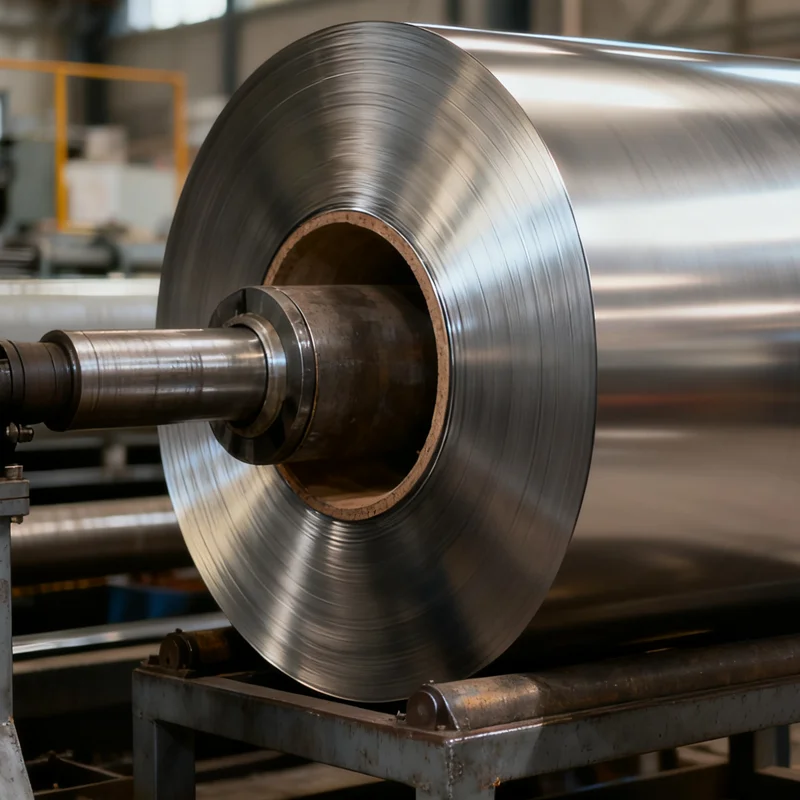

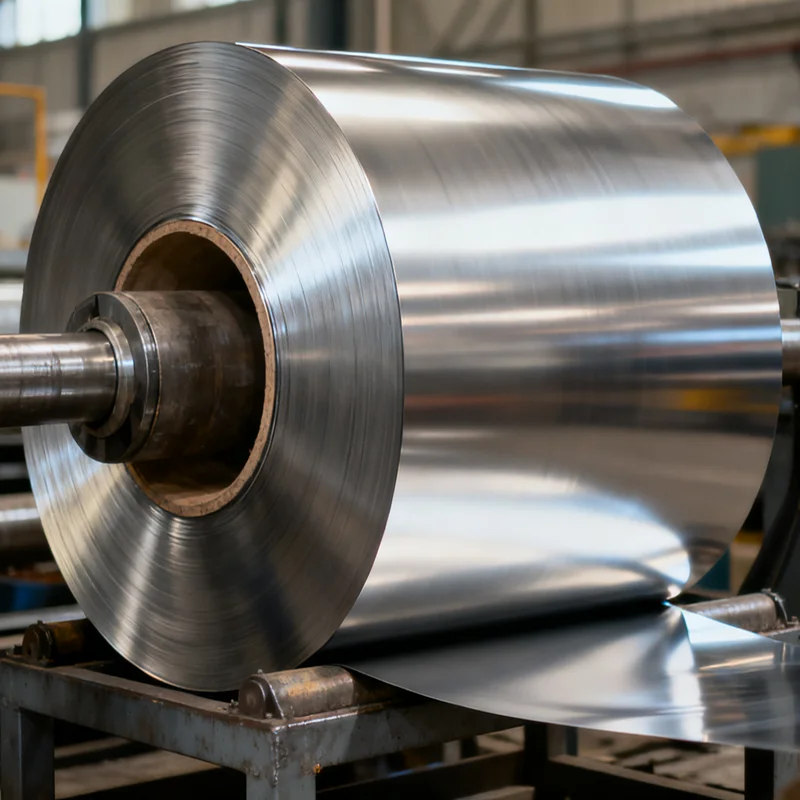

The cold-rolling manufacturing process employed in producing these coils results in enhanced surface quality and improved dimensional tolerances compared to hot-rolled alternatives. This precision manufacturing approach ensures consistent thickness throughout the coil length, facilitating downstream processing operations such as stamping, forming, and welding. The smooth surface finish achieved through cold-rolling also eliminates the need for additional surface preparation in many applications, reducing overall processing time and costs.

Available in carefully calibrated thicknesses, these stainless steel coils accommodate a broad spectrum of manufacturing requirements. The thinner gauge options excel in applications requiring intricate forming operations, while the heavier gauge materials provide enhanced structural integrity for load-bearing applications. This thickness variety ensures that manufacturers can select the most appropriate material specification for their specific application requirements.

Features & Benefits

Superior Corrosion Resistance

The chromium content in these stainless steel grades creates a passive oxide layer that provides exceptional resistance to corrosion in various environmental conditions. This inherent protection makes the coils suitable for applications exposed to moisture, chemicals, and atmospheric pollutants without requiring additional protective coatings. The enhanced corrosion resistance translates to extended service life and reduced maintenance requirements in finished products.

Exceptional Formability and Workability

Cold-rolled stainless steel coils exhibit superior formability characteristics that enable complex shaping operations without compromising material integrity. The refined grain structure achieved through the cold-rolling process enhances the material's ability to undergo deep drawing, bending, and other forming operations commonly required in manufacturing processes. This workability advantage reduces material waste and improves production efficiency in downstream manufacturing operations.

Consistent Quality and Dimensional Accuracy

The precision manufacturing processes employed in producing these Customized Stainless Steel Coils 201/304L/316/316L Stainless Steel Coils, Cold-rolled 0.5mm and 1.0mm Stainless Steel Coils ensure consistent material properties throughout each coil. Advanced quality control systems monitor thickness variations, surface finish, and mechanical properties to guarantee that every meter of coil meets specified tolerances. This consistency eliminates the need for extensive incoming material inspection and reduces processing variables in manufacturing operations.

Enhanced Surface Finish

The cold-rolling process creates a smooth, uniform surface finish that meets demanding aesthetic and functional requirements. This superior surface quality reduces the likelihood of defects in subsequent processing operations and often eliminates the need for additional surface preparation steps. The enhanced finish also contributes to improved paint adhesion and coating performance when surface treatments are required.

Applications & Use Cases

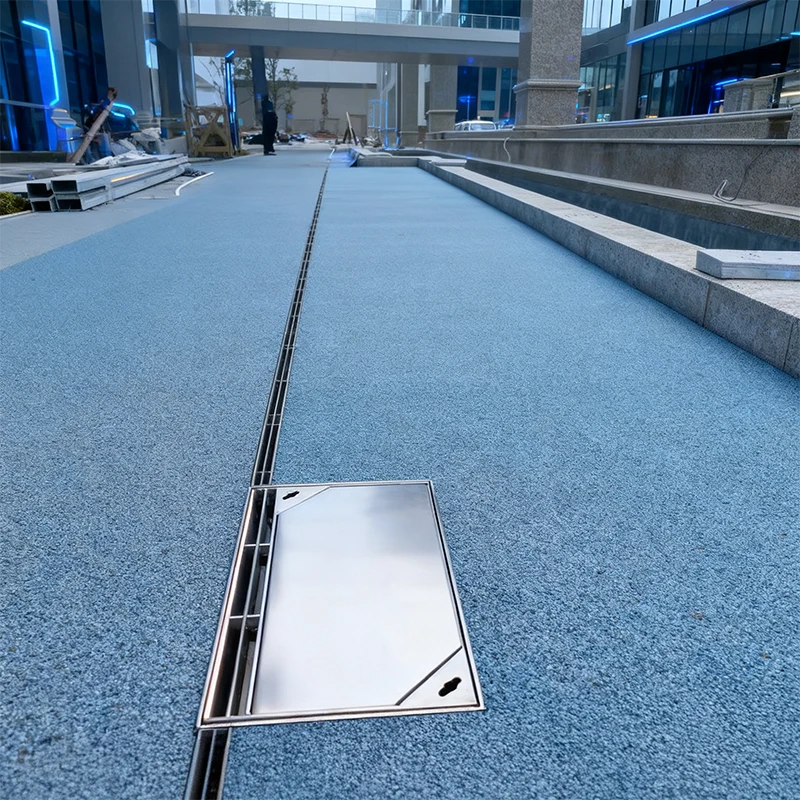

The versatility of these customized stainless steel coils makes them indispensable across numerous industrial sectors. In the architectural and construction industry, these materials serve as the foundation for exterior cladding systems, roofing applications, and decorative elements that require long-term durability and aesthetic appeal. The corrosion resistance and formability of the stainless steel grades enable the creation of complex architectural features while ensuring structural integrity over extended service periods.

Automotive manufacturers rely on these precision coils for producing exhaust systems, trim components, and structural elements that must withstand harsh operating environments. The excellent formability allows for the creation of complex geometries required in modern vehicle designs, while the corrosion resistance ensures component longevity despite exposure to road salt, moisture, and temperature variations. The consistent material properties also support automated manufacturing processes common in automotive production facilities.

The food processing and pharmaceutical industries benefit from the hygienic properties and easy cleanability of stainless steel surfaces produced from these coils. Equipment manufacturers utilize the material for creating tanks, conveyor systems, and processing equipment that must meet stringent sanitation requirements. The non-porous surface finish prevents bacterial growth and facilitates thorough cleaning procedures essential in these regulated industries.

In marine and coastal applications, the enhanced corrosion resistance of higher-grade stainless steel coils provides reliable performance in salt-water environments. Shipbuilding operations, offshore equipment manufacturing, and coastal infrastructure projects depend on these materials to resist the aggressive corrosive effects of marine atmospheres. The material's strength-to-weight ratio also contributes to improved fuel efficiency and reduced structural requirements in marine applications.

Quality Control & Compliance

Rigorous quality assurance protocols govern every stage of production for these Customized Stainless Steel Coils 201/304L/316/316L Stainless Steel Coils, Cold-rolled 0.5mm and 1.0mm Stainless Steel Coils. Advanced testing equipment continuously monitors chemical composition, mechanical properties, and dimensional characteristics to ensure conformance with international standards. This comprehensive quality control approach guarantees that delivered materials meet or exceed specified performance requirements consistently.

Chemical composition verification employs spectroscopic analysis techniques to confirm that chromium, nickel, and other alloying elements fall within specified ranges for each grade. Mechanical property testing validates tensile strength, yield strength, and elongation characteristics to ensure materials perform as expected in demanding applications. Surface quality inspection utilizes advanced optical systems to detect and eliminate any surface defects that could compromise finished product quality.

Dimensional accuracy verification employs precision measurement systems throughout the production process to maintain tight tolerances on thickness, width, and flatness characteristics. These measurements ensure compatibility with automated processing equipment and reduce material waste in customer manufacturing operations. Statistical process control methods track quality trends and enable proactive adjustments to maintain consistent output quality.

International standards compliance ensures global acceptance and facilitates international trade for distributors and end-users. Regular third-party audits verify adherence to quality management systems and validate the effectiveness of internal quality control procedures. This independent verification provides additional confidence for customers requiring documented quality assurance for their applications.

Customization & Branding Options

Understanding that different applications require specific material characteristics, our customization capabilities extend beyond standard grade offerings to accommodate unique customer requirements. Chemical composition modifications within grade specifications can optimize performance for specific environmental conditions or processing requirements. Surface finish variations, including different roughness levels and texture patterns, enable precise matching of aesthetic and functional requirements.

Dimensional customization encompasses width specifications tailored to customer processing equipment capabilities and waste minimization objectives. Custom slitting operations can provide multiple narrow widths from master coils, optimizing material utilization for specific product configurations. Length specifications can be adjusted to match customer inventory management practices and processing batch sizes, reducing handling requirements and storage costs.

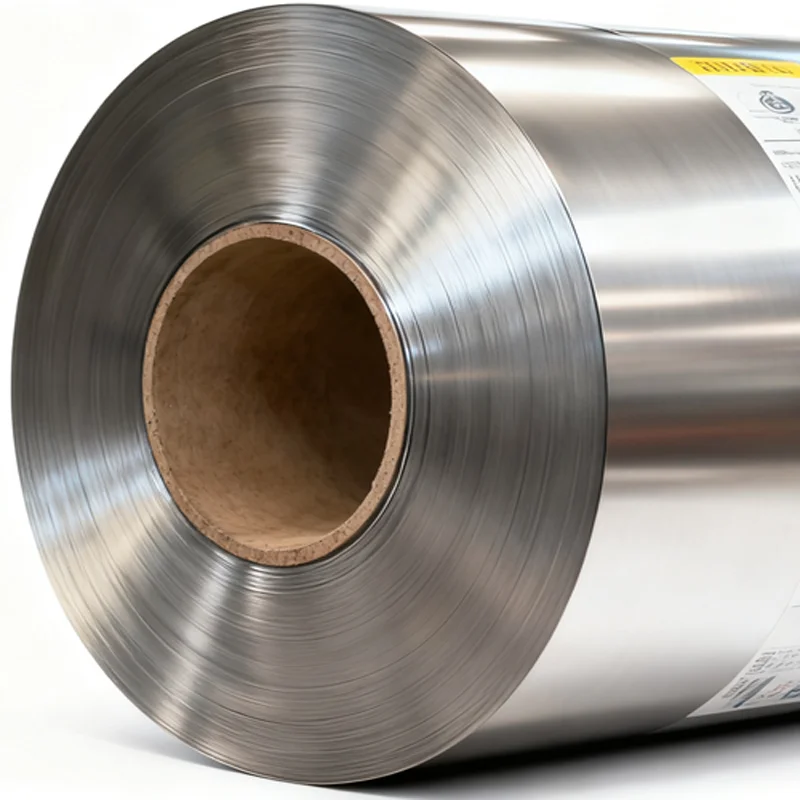

Packaging customization options include specialized protective wrapping materials and configurations designed to prevent surface damage during transportation and storage. Custom labeling and identification systems facilitate inventory management and traceability requirements in customer facilities. These packaging modifications ensure material condition integrity from production through final processing operations.

Technical support services complement customization options by providing application-specific guidance for material selection and processing optimization. Engineering consultation helps customers maximize material performance while minimizing processing costs and waste generation. This collaborative approach ensures that customized solutions deliver measurable value improvements in customer operations.

Packaging & Logistics Support

Professional packaging systems protect these precision stainless steel coils throughout the supply chain, ensuring delivery in pristine condition ready for immediate processing. Multi-layer protective wrapping prevents surface contamination and moisture exposure that could compromise material quality. Robust packaging materials withstand the rigors of international shipping while maintaining easy unpacking procedures at customer facilities.

Coil handling systems accommodate various transportation methods and customer receiving capabilities. Standard wooden pallets provide stable platforms for forklift handling, while specialized cradles prevent coil deformation during transportation. Custom packaging configurations can accommodate unique customer requirements or shipping constraints, ensuring successful delivery regardless of logistical challenges.

Documentation systems provide comprehensive material certification and traceability information accompanying each shipment. Test certificates verify chemical composition and mechanical properties, while dimensional inspection reports confirm conformance to specified tolerances. This documentation facilitates customer quality assurance procedures and supports regulatory compliance requirements in various industries.

Logistics coordination services streamline the supply chain process for international customers and distributors. Experienced logistics teams manage shipping documentation, customs requirements, and delivery scheduling to minimize transit times and reduce total landed costs. This comprehensive logistics support enables customers to focus on their core manufacturing activities while ensuring reliable material supply.

Why Choose Us

With decades of experience serving international markets, our company has established itself as a trusted metal packaging supplier and reliable source for premium stainless steel materials across diverse industries. Our global presence enables us to understand regional requirements and provide localized support while maintaining consistent quality standards worldwide. This international expertise translates to superior customer service and technical support regardless of geographic location.

Our comprehensive quality management systems and advanced manufacturing capabilities position us as a preferred custom metal packaging solutions provider for demanding applications. State-of-the-art production facilities incorporate the latest technology to ensure consistent output quality and efficient processing operations. Continuous investment in equipment upgrades and process improvements maintains our competitive advantage in delivering superior products.

Technical expertise spanning multiple industries enables us to provide valuable application guidance and material optimization recommendations. Our engineering team collaborates with customers to identify opportunities for performance improvements and cost reductions through material selection and processing optimization. This consultative approach creates lasting partnerships that benefit all stakeholders in the supply chain.

Environmental responsibility initiatives demonstrate our commitment to sustainable manufacturing practices and resource conservation. Advanced recycling programs minimize waste generation, while energy-efficient production processes reduce environmental impact. These sustainability efforts align with customer corporate responsibility objectives and support green building certification requirements in construction applications.

Conclusion

The Customized Stainless Steel Coils 201/304L/316/316L Stainless Steel Coils, Cold-rolled 0.5mm and 1.0mm Stainless Steel Coils represent an exceptional combination of quality, versatility, and performance that addresses the demanding requirements of modern manufacturing. These precision-engineered materials deliver consistent quality, superior formability, and outstanding corrosion resistance across diverse application environments. The comprehensive customization options, rigorous quality control procedures, and professional logistics support ensure successful implementation in customer operations worldwide. Whether serving architectural, automotive, food processing, or marine applications, these premium stainless steel coils provide the reliability and performance characteristics necessary for long-term success in competitive markets.