Introduction

Modern infrastructure demands reliable water management solutions that combine durability, aesthetic appeal, and functional excellence. Customized stainless steel drainage ditches for outdoor park metal building materials and eaves drainage systems represent the pinnacle of contemporary drainage engineering, offering unparalleled performance in diverse outdoor environments. These sophisticated drainage solutions address the critical need for effective water control in parks, commercial complexes, residential developments, and industrial facilities where traditional drainage methods fall short of meeting contemporary architectural and environmental standards.

The evolution of drainage technology has shifted toward materials that offer superior longevity and minimal maintenance requirements. Stainless steel drainage systems have emerged as the preferred choice for discerning architects, contractors, and facility managers who understand that investing in premium drainage infrastructure translates into long-term cost savings and enhanced property value. These advanced drainage solutions seamlessly integrate with modern building materials while providing exceptional resistance to environmental challenges that compromise conventional drainage systems.

Product Overview

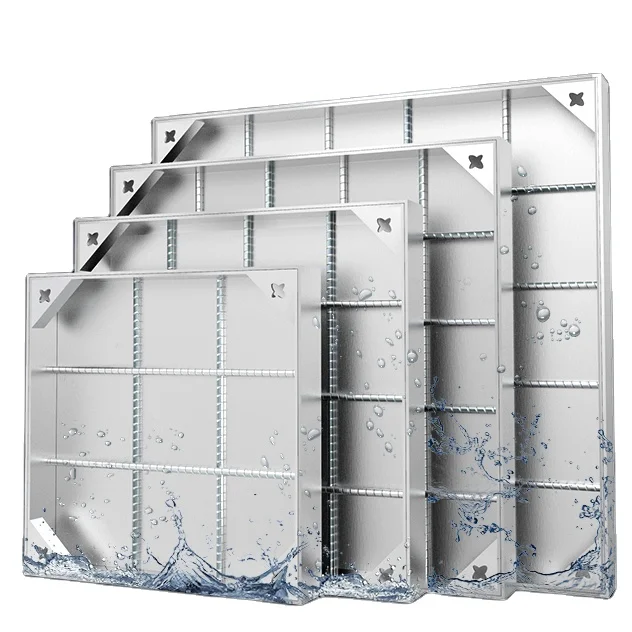

Our customized stainless steel drainage ditches for outdoor park metal building materials and eaves drainage systems are engineered to meet the demanding requirements of contemporary construction projects. These precision-manufactured drainage components feature advanced metallurgical properties that ensure optimal performance across varying climatic conditions and installation environments. The inherent characteristics of stainless steel provide exceptional corrosion resistance, structural integrity, and aesthetic versatility that makes these drainage systems suitable for both functional and decorative applications.

The manufacturing process incorporates state-of-the-art fabrication techniques that allow for precise customization according to specific project requirements. Each drainage system is designed to integrate seamlessly with existing architectural elements while maintaining the structural integrity necessary for effective water management. The versatility of stainless steel construction enables these drainage solutions to complement various building materials including concrete, stone, composite materials, and traditional metals, ensuring cohesive design integration regardless of the surrounding infrastructure.

These drainage systems are specifically engineered to handle the unique challenges associated with outdoor installations where exposure to environmental elements, temperature fluctuations, and varying water flow conditions require robust construction and reliable performance. The advanced design principles incorporated into these drainage solutions ensure optimal water flow characteristics while minimizing maintenance requirements and extending operational lifespan significantly beyond conventional drainage alternatives.

Features & Benefits

Superior Material Properties

The fundamental advantage of stainless steel construction lies in its exceptional resistance to corrosion, oxidation, and chemical deterioration that commonly affects other drainage materials. This inherent durability ensures that drainage systems maintain their structural integrity and aesthetic appearance throughout extended service periods, even when exposed to harsh environmental conditions including salt air, industrial pollutants, and aggressive chemical substances that may be present in urban environments.

The thermal stability of stainless steel provides consistent performance across extreme temperature ranges, preventing the expansion and contraction issues that often compromise drainage systems constructed from alternative materials. This thermal resilience ensures that connections remain secure and water flow characteristics remain consistent regardless of seasonal temperature variations or sudden weather changes that might affect drainage performance.

Enhanced Drainage Performance

The smooth internal surfaces characteristic of stainless steel construction promote optimal water flow efficiency while minimizing debris accumulation and blockage formation. This design advantage translates into reduced maintenance requirements and sustained drainage capacity over extended operational periods. The precision manufacturing processes employed in creating these drainage systems ensure consistent internal dimensions and smooth surface finishes that facilitate effective water evacuation even during high-volume precipitation events.

The structural strength of stainless steel enables the construction of drainage systems with optimized cross-sectional profiles that maximize water carrying capacity while maintaining compact external dimensions. This engineering advantage allows for effective drainage solutions in space-constrained applications where conventional drainage systems would require larger installation footprints or multiple drainage lines to achieve equivalent performance levels.

Aesthetic Integration

Modern architectural design increasingly demands drainage solutions that contribute positively to overall aesthetic appeal rather than merely providing functional utility. Stainless steel drainage systems offer exceptional design flexibility through various surface finishes, profile configurations, and integration options that allow seamless incorporation into contemporary architectural themes. The neutral appearance of stainless steel complements both traditional and modern design elements while maintaining a sophisticated professional appearance that enhances property value.

Applications & Use Cases

Public parks and recreational facilities represent primary applications for customized stainless steel drainage ditches for outdoor park metal building materials and eaves drainage systems where durability and aesthetic appeal are equally important considerations. These environments require drainage solutions capable of handling varying water volumes while maintaining safe conditions for public use. The smooth surfaces and robust construction of stainless steel drainage systems eliminate sharp edges and potential safety hazards while providing reliable water management throughout changing weather conditions.

Commercial and residential developments increasingly specify stainless steel drainage systems for their superior performance characteristics and low maintenance requirements. Shopping centers, office complexes, and mixed-use developments benefit from drainage solutions that maintain their appearance and functionality over extended periods without requiring frequent replacement or extensive maintenance procedures. The compatibility of stainless steel with modern building materials makes these drainage systems ideal for integration with contemporary architectural designs that emphasize clean lines and sophisticated material combinations.

Industrial facilities and manufacturing complexes require drainage solutions capable of withstanding exposure to various chemicals, oils, and industrial byproducts that would quickly deteriorate conventional drainage materials. Stainless steel construction provides the chemical resistance necessary for reliable performance in these demanding environments while maintaining the structural integrity required for heavy-duty industrial applications. The ease of cleaning and sanitizing stainless steel surfaces makes these drainage systems particularly suitable for food processing, pharmaceutical, and other industries with strict hygiene requirements.

Educational institutions, healthcare facilities, and government buildings increasingly choose stainless steel drainage systems for their combination of durability, safety, and aesthetic appeal. These installations require drainage solutions that can withstand heavy foot traffic, maintain hygienic conditions, and provide reliable performance with minimal maintenance intervention. The long-term cost effectiveness of stainless steel drainage systems makes them particularly attractive for public sector projects where budget considerations must balance initial investment with long-term operational costs.

Quality Control & Compliance

Manufacturing excellence begins with rigorous material selection processes that ensure only premium-grade stainless steel alloys are utilized in drainage system construction. Each batch of raw materials undergoes comprehensive testing to verify chemical composition, mechanical properties, and surface quality characteristics that directly impact final product performance. This commitment to material quality provides the foundation for drainage systems that consistently exceed industry standards for durability, corrosion resistance, and structural integrity.

The fabrication process incorporates multiple quality checkpoints that monitor dimensional accuracy, surface finish quality, and structural integrity throughout each manufacturing stage. Advanced inspection techniques including non-destructive testing methods ensure that every drainage component meets stringent quality standards before proceeding to final assembly. This comprehensive quality assurance approach eliminates defective components and ensures consistent product performance across all manufacturing batches.

Environmental compliance represents a critical consideration in modern manufacturing operations, and our drainage systems are produced using environmentally responsible processes that minimize waste generation and energy consumption. The recyclable nature of stainless steel construction contributes to sustainable building practices while providing end-of-life value that offsets initial material investments. These environmental benefits align with green building initiatives and LEED certification requirements that increasingly influence material selection decisions in contemporary construction projects.

International quality standards govern all aspects of production, ensuring that drainage systems meet or exceed requirements for various global markets. Regular third-party audits and certification renewals maintain compliance with evolving industry standards while providing customers with confidence in product quality and performance reliability. This commitment to standardized excellence facilitates international trade and ensures consistent product performance regardless of installation location or local environmental conditions.

Customization & Branding Options

Project-specific customization capabilities enable the creation of drainage solutions perfectly matched to unique architectural requirements and site conditions. Engineering teams work closely with clients to develop custom profiles, dimensions, and configuration options that optimize drainage performance while integrating seamlessly with existing infrastructure. This collaborative approach ensures that each installation achieves maximum efficiency while maintaining aesthetic coherence with surrounding architectural elements.

Surface treatment options provide additional customization possibilities that enhance both functional and aesthetic characteristics of drainage systems. Various finishing techniques including brushed, polished, and textured surfaces offer different visual effects while maintaining the fundamental performance advantages of stainless steel construction. These surface options allow designers to create drainage systems that complement specific architectural themes while providing optimal slip resistance and cleaning characteristics for different installation environments.

Branding integration opportunities allow commercial clients to incorporate corporate identity elements into their drainage infrastructure through discrete logo placement, custom color accents, or specialized surface treatments that reinforce brand recognition. These branding options maintain the professional appearance of drainage systems while providing subtle marketing opportunities that enhance corporate image and facility identification. The durability of stainless steel ensures that branding elements maintain their appearance throughout extended service periods without requiring renewal or maintenance.

Modular design principles enable the creation of drainage systems that can be easily expanded, modified, or reconfigured as facility requirements evolve. This flexibility provides long-term value by allowing drainage infrastructure to adapt to changing needs without requiring complete system replacement. The standardized connection interfaces ensure compatibility between different system components while maintaining structural integrity and performance characteristics throughout system modifications.

Packaging & Logistics Support

Professional packaging solutions protect drainage components throughout international shipping and handling processes while minimizing packaging waste and transportation costs. Custom packaging designs accommodate the unique dimensional characteristics of drainage systems while providing adequate protection against impact, moisture, and other shipping hazards that could compromise product quality. These packaging solutions are designed to facilitate efficient handling and installation while reducing on-site waste generation and disposal requirements.

Comprehensive documentation accompanies each shipment, providing detailed installation instructions, maintenance guidelines, and warranty information that ensures proper system implementation and long-term performance. Technical support materials include detailed drawings, specification sheets, and troubleshooting guides that assist installation teams in achieving optimal results while avoiding common installation errors that could compromise system performance or void warranty coverage.

Logistics coordination services streamline the delivery process by coordinating shipping schedules with project timelines and providing real-time tracking information that enables precise delivery planning. This coordination capability is particularly valuable for large-scale projects where drainage system installation must be synchronized with other construction activities to maintain project schedules and minimize on-site storage requirements.

International shipping expertise ensures compliance with customs requirements, documentation standards, and shipping regulations across different countries and regions. This knowledge base facilitates smooth customs clearance and reduces the risk of shipping delays that could impact project schedules. Established relationships with international freight carriers provide access to competitive shipping rates and reliable delivery services that support global project requirements.

Why Choose Us

Our company has established itself as a trusted metal packaging manufacturer with extensive experience serving diverse industries and international markets. This expertise extends beyond traditional packaging solutions to encompass sophisticated drainage systems that leverage our deep understanding of stainless steel fabrication techniques and quality control processes. Our commitment to excellence has earned recognition from clients worldwide who value the combination of technical expertise, manufacturing capability, and customer service that defines our approach to every project.

As a leading custom tin box supplier and provider of specialized metal solutions, we understand the importance of precision manufacturing and attention to detail that distinguishes superior products from conventional alternatives. This manufacturing philosophy applies equally to our drainage systems, where the same commitment to quality that has made us a preferred partner in packaging applications ensures exceptional performance in drainage infrastructure. Our ability to translate customer requirements into precisely engineered solutions reflects years of experience in custom metal fabrication across multiple industries and applications.

The global reach of our operations provides customers with access to international manufacturing capabilities while maintaining local support services that ensure responsive customer service and technical assistance. Our established supply chain relationships and manufacturing partnerships enable us to deliver consistent quality and reliable service regardless of project location or complexity. This international perspective combined with local expertise provides the foundation for successful project completion and long-term customer satisfaction.

Innovation drives our continuous improvement efforts as we invest in advanced manufacturing technologies, process optimization, and product development initiatives that maintain our competitive advantages in evolving markets. This commitment to innovation ensures that our drainage systems incorporate the latest advances in materials science, manufacturing techniques, and design optimization that deliver superior value to customers. Our research and development capabilities enable us to anticipate market trends and develop solutions that meet emerging customer needs before they become industry standards.

Conclusion

Customized stainless steel drainage ditches for outdoor park metal building materials and eaves drainage systems represent the optimal solution for modern infrastructure projects that demand superior performance, aesthetic appeal, and long-term reliability. These advanced drainage systems combine the inherent advantages of stainless steel construction with precision engineering and customization capabilities that address the unique requirements of diverse applications. The investment in premium drainage infrastructure delivers exceptional value through reduced maintenance costs, extended service life, and enhanced property value that far exceeds the benefits available from conventional drainage alternatives. Our commitment to manufacturing excellence, customer service, and continuous innovation ensures that these drainage systems will continue to provide reliable performance and aesthetic appeal throughout their extended operational lifespan, making them the preferred choice for discerning professionals who understand the importance of quality infrastructure investments.