Introduction

Infrastructure safety and aesthetic appeal converge in our Modern 304 Stainless Steel Invisible Recessed Manhole Covers Made of Industrial Steel Materials Are Durable, representing the pinnacle of contemporary civil engineering solutions. These sophisticated access covers seamlessly integrate into urban environments while maintaining exceptional structural integrity. Designed for discerning construction professionals and municipal authorities worldwide, these invisible recessed systems redefine how we approach underground utility access points. The fusion of premium stainless steel construction with innovative recessed design principles creates an unparalleled balance between functionality and visual discretion.

Product Overview

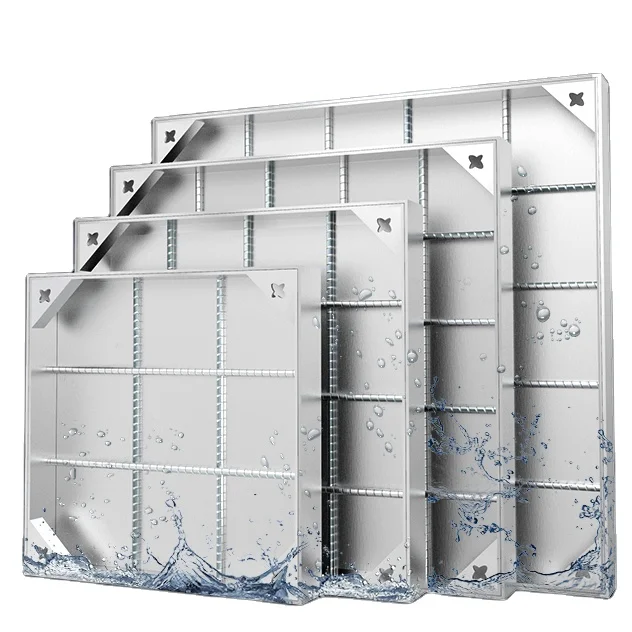

Our premium manhole cover systems utilize high-grade stainless steel composition to deliver unprecedented durability and longevity in demanding urban applications. The invisible recessed design philosophy ensures these essential infrastructure components remain virtually undetectable when properly installed, maintaining the aesthetic continuity of pedestrian areas, plazas, and architectural landscapes. Each unit demonstrates meticulous engineering precision, incorporating advanced metallurgy principles to achieve optimal strength-to-weight ratios while resisting environmental degradation.

The industrial steel materials employed in manufacturing these Modern 304 Stainless Steel Invisible Recessed Manhole Covers Made of Industrial Steel Materials Are Durable undergo rigorous quality assessment processes to ensure consistent performance across diverse climate conditions. The recessed configuration allows for seamless integration with surrounding surfaces, whether concrete, stone, or composite materials, creating flush installations that preserve architectural integrity while providing secure underground access.

Features & Benefits

Superior Material Composition

The stainless steel construction provides exceptional resistance to corrosion, oxidation, and chemical degradation, ensuring extended service life in challenging environmental conditions. This industrial-grade material selection demonstrates remarkable resilience against temperature fluctuations, moisture exposure, and chemical pollutants commonly found in urban environments. The inherent properties of stainless steel eliminate the need for frequent maintenance cycles, reducing long-term operational costs for facility managers and municipal authorities.

Innovative Recessed Design

The invisible recessed architecture represents a paradigm shift in manhole cover design philosophy, prioritizing visual harmony without compromising functional accessibility. This sophisticated approach eliminates traditional raised profiles that can create pedestrian hazards or disrupt vehicular traffic flow. The recessed configuration accommodates various surface finishes and materials, enabling architects and urban planners to maintain design continuity across complex infrastructure projects.

Enhanced Durability Characteristics

These Modern 304 Stainless Steel Invisible Recessed Manhole Covers Made of Industrial Steel Materials Are Durable exhibit remarkable resistance to impact damage, structural deformation, and surface wear patterns typically associated with heavy pedestrian traffic or vehicular loading. The industrial steel materials maintain structural integrity under extreme loading conditions while preserving smooth operation mechanisms throughout extended service periods. This durability translates directly into reduced replacement frequencies and minimized disruption to surrounding infrastructure systems.

Applications & Use Cases

Municipal infrastructure projects benefit tremendously from these advanced manhole cover systems, particularly in high-visibility areas where aesthetic considerations are paramount. Historic districts, commercial pedestrian zones, and luxury residential developments require infrastructure solutions that respect architectural heritage while meeting contemporary safety standards. The invisible recessed design seamlessly accommodates these demanding requirements, providing secure utility access without visual intrusion.

Commercial construction projects increasingly specify these premium access covers for corporate campuses, shopping centers, and hospitality venues where maintaining pristine surface appearances directly impacts business operations. The stainless steel construction ensures consistent performance in high-traffic environments while the recessed configuration prevents accumulation of debris or standing water that could compromise safety or cleanliness standards.

Industrial facilities and manufacturing complexes utilize these Modern 304 Stainless Steel Invisible Recessed Manhole Covers Made of Industrial Steel Materials Are Durable systems to maintain clean room environments and comply with stringent hygiene regulations. The smooth, non-porous stainless steel surfaces facilitate thorough cleaning protocols while the flush installation eliminates potential contamination collection points that traditional raised covers might create.

Quality Control & Compliance

Manufacturing excellence drives every aspect of our production methodology, ensuring each manhole cover system meets or exceeds international quality benchmarks. Comprehensive testing protocols evaluate structural performance, corrosion resistance, and operational reliability under simulated real-world conditions. These rigorous assessment procedures guarantee consistent product performance across diverse geographic markets and climatic zones.

Our quality management systems incorporate advanced metallurgical analysis to verify material composition and mechanical properties throughout the manufacturing process. Each production batch undergoes detailed inspection procedures that examine surface finish quality, dimensional accuracy, and functional mechanism operation. This systematic approach to quality control ensures that every Modern 304 Stainless Steel Invisible Recessed Manhole Covers Made of Industrial Steel Materials Are Durable unit delivered to customers maintains our established performance standards.

International compliance standards guide our design and manufacturing processes, ensuring compatibility with diverse regulatory frameworks across global markets. Our engineering team continuously monitors evolving industry standards and incorporates relevant updates into our production methodologies, maintaining currency with best practices in infrastructure safety and environmental responsibility.

Customization & Branding Options

Professional customization services accommodate unique project requirements and architectural specifications, enabling seamless integration with diverse design concepts. Our engineering capabilities support modifications to dimensions, surface treatments, and operational mechanisms while preserving the fundamental durability and safety characteristics that define these premium access systems. Custom surface textures and finishes can be specified to complement surrounding materials and maintain visual consistency across complex installations.

As an experienced metal packaging manufacturer with extensive expertise in stainless steel fabrication, we understand the importance of precise customization in meeting specific application requirements. Our design team collaborates closely with architects, engineers, and project managers to develop tailored solutions that address unique challenges while maintaining structural integrity and operational reliability. This collaborative approach ensures optimal performance in demanding environments while respecting aesthetic and functional constraints.

Branding integration opportunities allow facility owners and developers to incorporate corporate identity elements or wayfinding systems into manhole cover designs without compromising the invisible recessed concept. Subtle logo embedment or identification marking systems can be incorporated using advanced laser marking techniques that preserve surface integrity while providing necessary identification capabilities for maintenance and emergency response personnel.

Packaging & Logistics Support

Professional packaging methodologies protect these precision-engineered products during international transportation and storage phases. Each manhole cover system receives individual protective wrapping and cushioning materials specifically selected to prevent surface damage and maintain dimensional accuracy throughout extended supply chains. Our logistics partners understand the critical importance of handling these premium infrastructure components with appropriate care and attention.

Comprehensive documentation accompanies each shipment, including installation guidelines, technical specifications, and maintenance recommendations tailored to specific project requirements. This detailed information supports efficient project execution while ensuring optimal performance throughout the service life of each installation. Our logistics coordination capabilities accommodate diverse delivery schedules and geographic destinations, facilitating smooth integration into complex construction timelines.

Environmental responsibility guides our packaging material selection, utilizing recyclable and sustainable materials wherever possible while maintaining protective effectiveness. This commitment to environmental stewardship aligns with the sustainable infrastructure development principles that increasingly influence modern construction practices and municipal policy decisions.

Why Choose Us

Our organization brings decades of specialized experience in precision metal fabrication and infrastructure component manufacturing to every project, ensuring reliable performance and customer satisfaction across international markets. This extensive background in serving diverse industries provides deep understanding of varying application requirements and performance expectations, enabling us to deliver solutions that exceed customer expectations consistently.

As a recognized custom tin box supplier and metal fabrication specialist, we leverage advanced manufacturing technologies and quality management systems to maintain competitive advantages in precision, reliability, and customer service. Our global supply chain capabilities support efficient project execution across diverse geographic markets while maintaining consistent quality standards and technical support services.

Technical expertise accumulated through extensive collaboration with architects, engineers, and construction professionals worldwide informs our continuous product development initiatives. This collaborative approach ensures our Modern 304 Stainless Steel Invisible Recessed Manhole Covers Made of Industrial Steel Materials Are Durable systems remain at the forefront of infrastructure technology while meeting evolving safety, environmental, and aesthetic requirements in contemporary construction practices.

Conclusion

These exceptional manhole cover systems represent the convergence of advanced materials science, innovative design philosophy, and precision manufacturing expertise, delivering unparalleled value to infrastructure projects worldwide. The combination of premium stainless steel construction with invisible recessed design principles creates solutions that satisfy both functional requirements and aesthetic aspirations without compromise. Through rigorous quality control, comprehensive customization capabilities, and professional logistics support, these Modern 304 Stainless Steel Invisible Recessed Manhole Covers Made of Industrial Steel Materials Are Durable systems establish new benchmarks for infrastructure excellence, providing reliable performance and visual discretion that enhance urban environments while ensuring safe, accessible utility management for generations to come.