Introduction

In the dynamic world of interior design and construction, achieving clean, professional finishes requires attention to even the smallest details. The transition between different surfaces, particularly where ceramic tiles meet walls or other materials, demands specialized solutions that combine functionality with aesthetic appeal. Customized Full-tiled Decorative Stainless Steel Profiles L-shaped Bathroom and Kitchen Corner Edges Ceramic Metal Strips represent a sophisticated approach to addressing these critical junction points, offering both protective properties and enhanced visual continuity throughout residential and commercial spaces.

These precision-engineered profiles serve as essential components in modern construction projects, where quality finishing touches distinguish exceptional installations from ordinary ones. By incorporating high-grade stainless steel construction with customizable design options, these L-shaped edge profiles provide architects, designers, and contractors with versatile solutions that meet diverse project requirements while maintaining consistent quality standards across various applications.

Product Overview

The Customized Full-tiled Decorative Stainless Steel Profiles L-shaped Bathroom and Kitchen Corner Edges Ceramic Metal Strips are meticulously crafted to provide seamless integration between ceramic surfaces and adjacent walls or structures. These specialized profiles feature a distinctive L-shaped configuration that accommodates the natural geometry of corner installations while providing robust protection against moisture, impact, and normal wear associated with high-traffic areas.

Manufactured from premium stainless steel alloys, these profiles demonstrate exceptional resistance to corrosion, staining, and temperature fluctuations commonly encountered in bathroom and kitchen environments. The material composition ensures long-term dimensional stability while maintaining its lustrous appearance throughout extended service periods. The full-tiled design approach allows for complete integration with existing ceramic installations, creating continuous surface transitions that enhance overall design cohesion.

Each profile undergoes precision forming processes that ensure consistent dimensional accuracy and smooth surface finishes. The manufacturing methodology incorporates advanced metalworking techniques that preserve material integrity while achieving the complex geometries required for effective corner protection and aesthetic enhancement. This attention to manufacturing excellence results in products that meet stringent international quality standards while providing reliable performance across diverse installation scenarios.

Features & Benefits

Superior Material Properties

The stainless steel construction provides inherent advantages that make these profiles particularly suitable for demanding environments. The material's natural resistance to oxidation eliminates concerns about rust formation, even in consistently humid conditions typical of bathroom and kitchen installations. This corrosion resistance extends product lifespan significantly compared to alternative materials, reducing long-term maintenance requirements and replacement costs.

The non-porous surface characteristics of stainless steel prevent bacterial growth and simplify cleaning procedures, making these profiles ideal for applications where hygiene standards are paramount. The material's thermal stability ensures dimensional consistency across temperature variations, preventing gaps or misalignment issues that could compromise installation integrity over time.

Precision Engineering and Design

The L-shaped configuration represents optimal geometry for corner applications, providing comprehensive coverage while minimizing material usage. This design efficiently protects vulnerable edge areas where ceramic tiles typically require additional support and protection. The profile geometry accommodates standard tile thicknesses while providing sufficient overlap to ensure secure attachment and weatherproof sealing.

Manufacturing precision ensures consistent profile dimensions that facilitate straightforward installation procedures. The uniformity of these Customized Full-tiled Decorative Stainless Steel Profiles L-shaped Bathroom and Kitchen Corner Edges Ceramic Metal Strips eliminates field adjustment requirements, reducing installation time and improving overall project efficiency. The smooth surface finish enhances visual appeal while preventing debris accumulation in textured areas.

Versatile Application Potential

These profiles demonstrate remarkable adaptability across various installation scenarios, from residential renovations to large-scale commercial projects. The customizable nature of the product allows for adaptation to specific project requirements, including modified dimensions, surface treatments, and specialized configurations that address unique architectural challenges.

The decorative potential extends beyond purely functional applications, as these profiles can serve as design elements that complement contemporary aesthetic preferences. The reflective properties of stainless steel contribute to enhanced lighting effects in interior spaces while providing visual continuity between different surface materials and textures.

Applications & Use Cases

Bathroom installations represent primary applications for these specialized profiles, where moisture resistance and hygiene considerations are paramount. The profiles provide essential protection for tile edges around bathtubs, shower enclosures, and vanity areas where water exposure is frequent and prolonged. The seamless integration with ceramic surfaces prevents water infiltration behind tiles, which could lead to structural damage or mold growth over time.

Kitchen environments benefit significantly from these profiles, particularly in areas around countertops, backsplashes, and appliance installations where food preparation activities create challenging conditions for traditional finishing materials. The easy-clean properties of stainless steel align perfectly with commercial kitchen requirements while providing residential installations with professional-grade performance characteristics.

Commercial applications extend to healthcare facilities, educational institutions, and hospitality environments where durability and maintenance efficiency are critical considerations. The profiles contribute to overall facility hygiene protocols while providing long-term aesthetic consistency that reduces renovation frequency and associated costs. Restaurant and food service establishments particularly value the sanitary properties and visual appeal of these Customized Full-tiled Decorative Stainless Steel Profiles L-shaped Bathroom and Kitchen Corner Edges Ceramic Metal Strips.

Retail environments utilize these profiles to create professional appearances in customer-facing areas while ensuring durability under high-traffic conditions. The reflective properties enhance lighting effectiveness, contributing to improved product displays and overall ambiance. Public restrooms and common areas benefit from the vandal-resistant properties and low maintenance requirements of stainless steel construction.

Quality Control & Compliance

Manufacturing processes incorporate comprehensive quality assurance protocols that ensure consistent product performance across production batches. Raw material verification procedures confirm alloy composition and mechanical properties meet specified standards before processing begins. Each production stage includes inspection checkpoints that monitor dimensional accuracy, surface quality, and structural integrity.

Environmental compliance considerations guide material selection and processing methodologies, ensuring products meet international standards for sustainable construction practices. The recyclable nature of stainless steel aligns with green building initiatives while providing end-of-life disposal options that minimize environmental impact. Manufacturing facilities maintain certifications that demonstrate commitment to responsible production practices and worker safety protocols.

Testing procedures validate product performance under simulated service conditions, including accelerated corrosion testing, thermal cycling, and mechanical stress evaluation. These comprehensive assessment protocols ensure products maintain specified performance characteristics throughout anticipated service life. Documentation systems provide traceability for quality verification and regulatory compliance requirements across international markets.

International standards compliance ensures products meet regional building codes and installation requirements across diverse markets. Regular auditing procedures verify ongoing adherence to quality management systems and continuous improvement initiatives. This systematic approach to quality control provides customers with confidence in product reliability and consistent performance expectations.

Customization & Branding Options

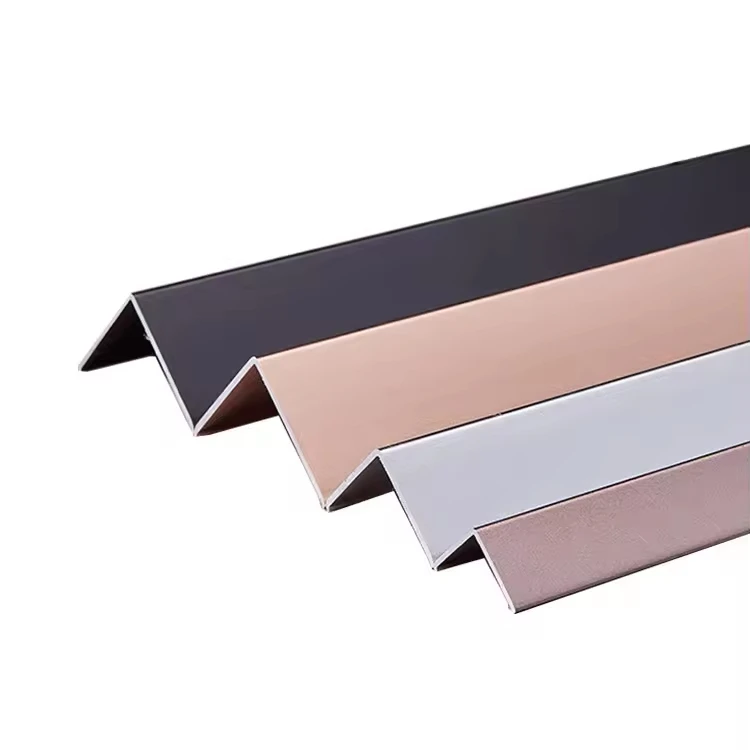

The customizable nature of these profiles enables adaptation to specific project requirements and aesthetic preferences. Surface finishing options include brushed, polished, and textured treatments that complement various design themes while maintaining functional performance characteristics. Custom length specifications accommodate unique architectural features and installation constraints without compromising structural integrity.

Color matching capabilities allow integration with existing design palettes through specialized coating applications or natural stainless steel tones. The profiles can incorporate subtle branding elements or decorative patterns that enhance visual appeal while maintaining professional appearance standards. These customization options make the Customized Full-tiled Decorative Stainless Steel Profiles L-shaped Bathroom and Kitchen Corner Edges Ceramic Metal Strips suitable for signature projects requiring distinctive design elements.

Engineering support services assist with custom profile development for unique applications or specialized performance requirements. Technical consultation ensures optimal profile geometry for specific installation scenarios while maintaining manufacturing efficiency and cost-effectiveness. Prototype development capabilities enable validation of custom designs before full production commitment.

Private labeling options allow distributors and contractors to develop brand recognition while offering quality products to their customer base. Packaging customization supports marketing initiatives and professional presentation requirements for high-end projects. These branding opportunities help establish market differentiation while maintaining product quality standards.

Packaging & Logistics Support

Protective packaging systems ensure product integrity during transportation and storage, utilizing materials that prevent surface damage while facilitating efficient handling procedures. Packaging design considerations include stackability for warehouse optimization and clear identification systems for inventory management. The packaging approach balances protection requirements with environmental responsibility through recyclable material selection.

Logistics coordination services support international distribution requirements, including documentation preparation and customs compliance assistance. Consolidated shipping options optimize transportation efficiency while reducing environmental impact and total cost considerations. Flexible shipping arrangements accommodate various order quantities and delivery schedule requirements across global markets.

Inventory management support helps distributors optimize stock levels while ensuring product availability for time-sensitive projects. Technical literature and installation guidelines accompany shipments to ensure proper handling and installation procedures. Digital documentation systems provide easy access to product specifications and installation instructions through secure online platforms.

As a metal packaging manufacturer with extensive experience in international markets, the company provides comprehensive logistics support that addresses diverse regional requirements. This global perspective ensures smooth product delivery while maintaining quality standards throughout the distribution chain. The logistics infrastructure supports both large-scale commercial projects and smaller specialized applications with equal efficiency and attention to detail.

Why Choose Us

With decades of experience serving international markets, our company has established a reputation for delivering high-quality metal solutions that exceed customer expectations. Our expertise spans multiple industries, providing deep understanding of diverse application requirements and performance standards. This comprehensive market knowledge enables us to develop products that address real-world challenges while maintaining competitive advantages in quality and innovation.

As a recognized metal packaging supplier, we maintain strategic partnerships with leading material suppliers and technology providers, ensuring access to the latest manufacturing capabilities and quality control systems. Our global presence enables responsive customer support and technical assistance across multiple time zones and languages. This international infrastructure supports seamless collaboration with customers worldwide while maintaining consistent quality standards.

Our commitment to continuous improvement drives ongoing investment in manufacturing technology and process optimization. Advanced quality management systems ensure consistent product performance while enabling rapid response to custom requirements and market changes. The combination of traditional craftsmanship expertise and modern manufacturing capabilities provides unique advantages in product development and delivery reliability.

Technical expertise extends beyond manufacturing to include application engineering and installation support services. Our team provides consultation on optimal product selection and implementation strategies that maximize project success while minimizing potential complications. This comprehensive support approach distinguishes our Customized Full-tiled Decorative Stainless Steel Profiles L-shaped Bathroom and Kitchen Corner Edges Ceramic Metal Strips from standard commodity products available in the marketplace.

Conclusion

The Customized Full-tiled Decorative Stainless Steel Profiles L-shaped Bathroom and Kitchen Corner Edges Ceramic Metal Strips represent a superior solution for modern construction and renovation projects requiring professional-grade finishing materials. The combination of premium stainless steel construction, precision engineering, and customization flexibility provides architects, contractors, and designers with reliable tools for achieving exceptional results in demanding environments. These profiles successfully bridge the gap between functional necessity and aesthetic enhancement, delivering long-term value through superior performance characteristics and visual appeal. The comprehensive support services and international expertise behind these products ensure successful project outcomes while maintaining the highest standards of quality and customer satisfaction throughout the entire product lifecycle.