Introduction

In today's demanding industrial landscape, precision-engineered stainless steel components form the backbone of countless manufacturing processes across diverse sectors. The Customized Matte Stainless Steel Strip Width 0.5mm/304L, 316L, 904L Grade, 316Ti Cutting, Bending, Welding Service Processing represents a comprehensive solution for businesses requiring ultra-thin, high-performance metal strips with exceptional surface finish and processing capabilities. This advanced material offering combines superior metallurgical properties with versatile fabrication services, enabling manufacturers to achieve precise specifications while maintaining the highest standards of durability and corrosion resistance.

Modern industrial applications increasingly demand materials that can withstand harsh operating environments while maintaining dimensional stability and aesthetic appeal. Our matte-finished stainless steel strips deliver exceptional performance characteristics that meet these stringent requirements, offering manufacturers a reliable foundation for their most critical applications. The combination of premium-grade alloys and specialized processing services ensures that each component meets exacting standards for both functional performance and visual presentation.

Product Overview

The Customized Matte Stainless Steel Strip Width 0.5mm/304L, 316L, 904L Grade, 316Ti Cutting, Bending, Welding Service Processing encompasses a comprehensive range of ultra-thin stainless steel materials engineered for precision applications. These strips feature a sophisticated matte surface treatment that eliminates reflective properties while maintaining the inherent strength and corrosion resistance characteristics of premium stainless steel alloys. The narrow width configuration makes these strips particularly suitable for applications requiring precise dimensional control and minimal material waste.

Each grade within this product range offers distinct advantages tailored to specific application requirements. The austenitic stainless steel variants provide excellent formability and weldability, while the super-austenitic options deliver enhanced resistance to aggressive chemical environments. The titanium-stabilized grades offer superior high-temperature performance and resistance to intergranular corrosion, making them ideal for demanding industrial processes where material integrity is paramount.

The matte surface finish achieved through controlled processing techniques provides uniform light diffusion properties while maintaining the material's mechanical strength. This specialized surface treatment eliminates the need for additional finishing operations in many applications, reducing processing time and associated costs while ensuring consistent appearance across large production runs.

Features & Benefits

Superior Material Properties

The exceptional metallurgical characteristics of these stainless steel strips ensure reliable performance across a wide range of operating conditions. The austenitic microstructure provides excellent ductility and toughness, enabling complex forming operations without compromising material integrity. Enhanced corrosion resistance properties make these strips suitable for exposure to various chemical environments, including those containing chlorides, acids, and alkaline solutions.

Temperature stability represents another key advantage, with these materials maintaining their mechanical properties across extended temperature ranges. The low carbon content in selected grades minimizes the risk of carbide precipitation, ensuring long-term durability in applications involving thermal cycling or elevated temperature exposure.

Advanced Surface Technology

The proprietary matte finishing process creates a uniform, non-reflective surface that enhances both aesthetic appeal and functional performance. This specialized treatment reduces glare and light reflection, making these strips ideal for applications in optical systems, architectural elements, and precision instruments where controlled light behavior is essential.

The matte surface also provides enhanced adhesion characteristics for subsequent coating or bonding operations, eliminating the need for additional surface preparation steps. This feature significantly streamlines manufacturing processes while ensuring superior bond strength and coating durability in finished products.

Comprehensive Processing Capabilities

Our integrated cutting, bending, and welding services transform raw material into precisely engineered components ready for immediate integration into customer applications. Advanced laser cutting technology ensures clean, burr-free edges with minimal heat-affected zones, preserving the material's metallurgical properties throughout the cutting process.

Precision bending operations utilize specialized tooling designed for ultra-thin materials, achieving tight radius bends without cracking or surface damage. The welding services employ appropriate filler materials and controlled atmosphere techniques to maintain corrosion resistance and mechanical properties in welded joints, ensuring seamless integration of multiple components.

Applications & Use Cases

The versatility of the Customized Matte Stainless Steel Strip Width 0.5mm/304L, 316L, 904L Grade, 316Ti Cutting, Bending, Welding Service Processing makes it an essential component across numerous industrial sectors. In the electronics industry, these strips serve as precision shielding elements, connector components, and heat dissipation elements where electromagnetic compatibility and thermal management are critical considerations. The matte surface finish prevents unwanted light reflection in optical devices while maintaining excellent electrical conductivity properties.

Automotive applications benefit from the superior formability and corrosion resistance of these materials, particularly in exhaust systems, fuel delivery components, and decorative trim elements. The narrow width configuration enables precise fitting in space-constrained assemblies while the various alloy grades provide optimal performance characteristics for specific operating environments within vehicle systems.

Medical device manufacturing represents another significant application area where the biocompatible properties and easy sterilization characteristics of these stainless steel strips prove invaluable. Surgical instruments, implantable devices, and diagnostic equipment components require materials that maintain their properties through repeated sterilization cycles while providing excellent corrosion resistance in biological environments.

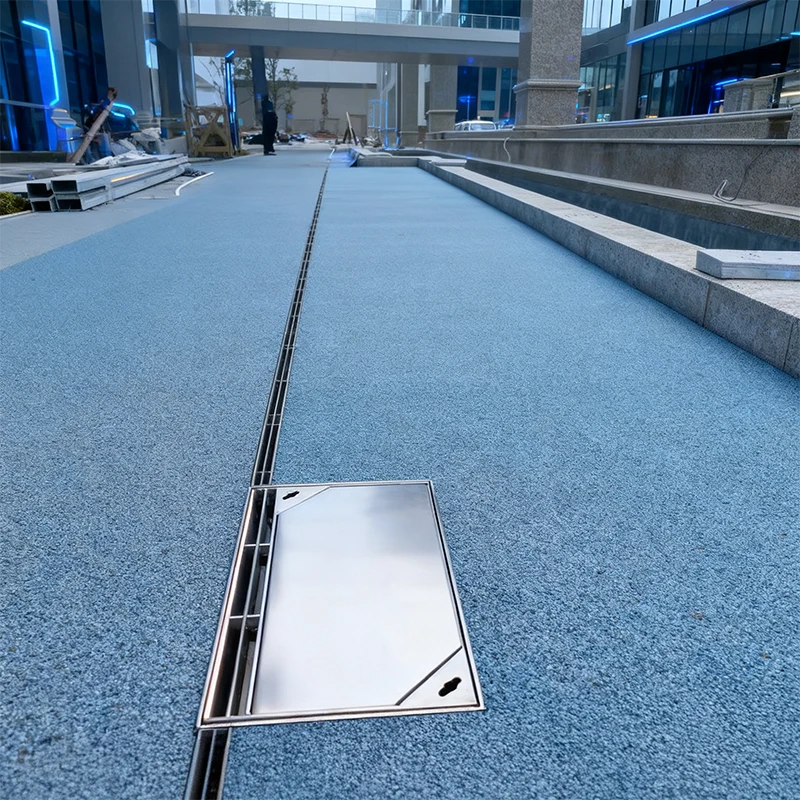

Architectural and construction applications utilize these strips for decorative elements, structural components, and weathering-resistant hardware. The matte finish provides an elegant appearance that complements modern design aesthetics while the underlying stainless steel properties ensure long-term durability in exterior environments exposed to weathering and atmospheric corrosion.

Quality Control & Compliance

Rigorous quality assurance protocols govern every aspect of material production and processing to ensure consistent delivery of premium-grade products. Advanced metallurgical testing verifies chemical composition, mechanical properties, and microstructural characteristics against established industry standards. Non-destructive testing methods including ultrasonic inspection and eddy current testing identify any subsurface discontinuities that could compromise performance in service.

Surface quality assessment employs sophisticated measurement techniques to verify finish uniformity, roughness parameters, and dimensional accuracy across the entire strip length. Statistical process control methods monitor production variables in real-time, enabling immediate corrective actions to maintain consistent quality output. Documentation packages accompanying each shipment provide complete traceability information including material certifications, test results, and processing records.

International compliance standards guide material selection and processing procedures, ensuring compatibility with global regulatory requirements across various industries. Regular third-party audits verify adherence to quality management systems and validate the effectiveness of implemented control measures. This comprehensive approach to quality assurance provides customers with confidence in material reliability and performance consistency.

Customization & Branding Options

Extensive customization capabilities enable precise adaptation of the Customized Matte Stainless Steel Strip Width 0.5mm/304L, 316L, 904L Grade, 316Ti Cutting, Bending, Welding Service Processing to meet specific application requirements. Length optimization services ensure minimal material waste while accommodating unique dimensional specifications for customer products. Edge conditioning options include deburred, rounded, or specially prepared edges depending on subsequent processing or assembly requirements.

Surface modification services extend beyond standard matte finishing to include specialized textures, patterns, or protective coatings that enhance performance in specific environments. Laser marking capabilities enable permanent identification codes, logos, or tracking information directly on the material surface without compromising structural integrity or corrosion resistance properties.

Custom packaging solutions protect material integrity during transportation and storage while facilitating efficient handling in customer facilities. Specialized coiling, spooling, or flat packaging options accommodate various material handling systems and production line configurations. Protective interleaving materials prevent surface damage during storage and handling operations.

Packaging & Logistics Support

Professional packaging protocols ensure material protection throughout the supply chain while optimizing shipping efficiency and reducing transportation costs. Moisture-resistant packaging materials prevent oxidation and contamination during extended storage periods, particularly important for maintaining surface quality in humid environments. Cushioning systems protect against mechanical damage during handling and transportation operations.

Inventory management services provide flexible supply arrangements that align with customer production schedules and minimize working capital requirements. Strategic warehouse locations enable rapid response to urgent requirements while maintaining consistent material availability for regular production needs. Advanced logistics coordination ensures timely delivery while providing shipment tracking capabilities and delivery confirmation services.

Documentation support includes comprehensive material certificates, inspection reports, and handling instructions that facilitate smooth integration into customer quality systems. Custom labeling options provide clear identification and traceability information while conforming to customer material management procedures and regulatory requirements.

Why Choose Us

With extensive experience serving international markets across diverse industrial sectors, our organization has established a reputation for delivering exceptional quality stainless steel products and processing services. Our comprehensive understanding of global manufacturing requirements enables us to provide solutions that meet the most demanding specifications while supporting efficient production operations. This proven track record of success demonstrates our commitment to customer satisfaction and continuous improvement in all aspects of our operations.

As a recognized metal packaging supplier and custom fabrication specialist, we leverage advanced manufacturing technologies and experienced engineering expertise to deliver innovative solutions for complex application challenges. Our integrated approach combines material science knowledge with practical manufacturing experience, enabling us to recommend optimal material selections and processing techniques for specific customer requirements. This collaborative methodology ensures successful project outcomes while minimizing development time and associated costs.

Our global presence and established supply chain relationships provide reliable access to premium raw materials and specialized processing capabilities. Strategic partnerships with international logistics providers ensure efficient worldwide distribution while maintaining competitive delivery schedules. Continuous investment in advanced equipment and process improvements demonstrates our commitment to maintaining technological leadership in precision stainless steel processing and fabrication services.

Conclusion

The Customized Matte Stainless Steel Strip Width 0.5mm/304L, 316L, 904L Grade, 316Ti Cutting, Bending, Welding Service Processing represents the pinnacle of precision-engineered stainless steel solutions for demanding industrial applications. Through the combination of superior metallurgical properties, advanced surface treatment technology, and comprehensive processing capabilities, this product offering delivers exceptional value for manufacturers requiring reliable, high-performance materials. The extensive customization options and integrated fabrication services streamline production workflows while ensuring optimal material utilization and consistent quality outcomes. Whether supporting complex manufacturing operations or enabling innovative product designs, these precision-engineered stainless steel strips provide the foundation for successful project execution across diverse industrial sectors.