Introduction

In today's competitive manufacturing landscape, sourcing premium stainless steel materials requires partnering with suppliers who understand the complexities of modern industrial applications. Our Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale represents the pinnacle of metallurgical excellence, designed to meet the exacting standards of international distributors, manufacturers, and industrial processors. These versatile steel coils combine superior corrosion resistance with exceptional workability, making them indispensable for applications spanning automotive components, architectural elements, food processing equipment, and precision manufacturing systems.

The comprehensive range encompasses multiple grade options, each engineered to deliver specific performance characteristics that align with diverse industrial requirements. Whether your operation demands the cost-effective properties of austenitic stainless steel or the enhanced corrosion resistance of marine-grade alloys, our product portfolio provides solutions that balance performance, durability, and economic efficiency. The sophisticated manufacturing processes employed ensure consistent mechanical properties and surface quality across every coil, enabling seamless integration into downstream fabrication processes.

Product Overview

Our Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale encompasses a comprehensive selection of austenitic stainless steel grades, each formulated to address specific industrial challenges. The product line features three primary grades that represent the most widely specified stainless steel alloys in global manufacturing applications. Grade two-zero-one offers an economical solution for applications requiring moderate corrosion resistance and good formability, making it ideal for decorative applications and light structural components.

Grade three-zero-four represents the industry standard for stainless steel applications, providing excellent corrosion resistance, superior weldability, and outstanding mechanical properties across a wide temperature range. This versatile grade serves as the backbone for countless industrial applications, from kitchen equipment manufacturing to pharmaceutical processing systems. Grade three-one-six elevates performance standards with enhanced corrosion resistance, particularly in chloride environments, making it the preferred choice for marine applications, chemical processing equipment, and medical device manufacturing.

The manufacturing process incorporates both hot-rolling and cold-rolling techniques to achieve optimal mechanical properties and surface characteristics. Hot-rolling provides the foundational structure and grain refinement, while subsequent cold-rolling operations deliver precise dimensional control and enhanced surface finish. The polished finish represents the culmination of sophisticated surface treatment processes that eliminate surface irregularities and create the mirror-like appearance demanded by high-end applications.

Features & Benefits

Superior Corrosion Resistance

The chromium-rich composition of our stainless steel coils creates a passive oxide layer that provides exceptional protection against atmospheric corrosion, chemical attack, and environmental degradation. This inherent corrosion resistance eliminates the need for additional protective coatings in most applications, reducing lifecycle costs and maintenance requirements. The austenitic microstructure ensures consistent performance across varying temperature conditions, maintaining structural integrity and appearance throughout extended service life.

Exceptional Formability and Workability

Advanced metallurgical engineering ensures optimal balance between strength and ductility, enabling complex forming operations without compromising material integrity. The refined grain structure achieved through controlled rolling processes enhances deep-drawing capabilities, bend formability, and stretch-forming performance. This superior workability translates directly into increased manufacturing efficiency and reduced scrap rates during fabrication operations.

Consistent Dimensional Accuracy

Precision cold-rolling operations deliver exceptional thickness uniformity and dimensional stability across the entire coil width and length. This consistency ensures predictable performance during automated processing operations and minimizes material waste during fabrication. The controlled surface finish provides uniform appearance and consistent material properties that meet the stringent requirements of high-visibility applications and precision manufacturing processes.

Applications & Use Cases

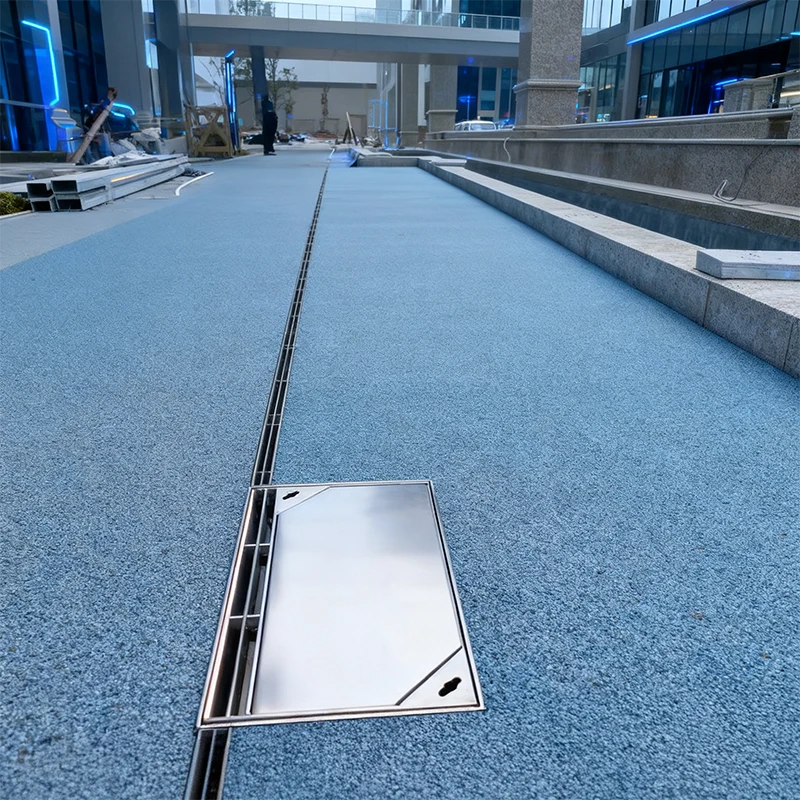

The versatility of our Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale makes it indispensable across numerous industrial sectors. In the architectural and construction industry, these materials serve as the foundation for curtain wall systems, roofing applications, decorative panels, and structural components that demand both aesthetic appeal and long-term durability. The polished surface finish provides the mirror-like appearance essential for modern architectural design while maintaining the structural properties required for demanding construction applications.

Food processing and pharmaceutical manufacturing represent critical application areas where material purity and corrosion resistance are paramount. The non-reactive surface characteristics ensure product safety while the smooth finish facilitates thorough cleaning and sanitization procedures. Equipment manufacturers rely on these materials for fabricating processing vessels, conveyor systems, storage tanks, and precision instrumentation that must maintain hygiene standards while withstanding aggressive cleaning chemicals and temperature extremes.

Automotive and transportation applications benefit from the combination of strength, corrosion resistance, and formability that enables complex component geometries. Exhaust system components, decorative trim elements, structural reinforcements, and fuel system components leverage the superior performance characteristics to meet increasingly stringent environmental and safety requirements. The consistent material properties ensure reliable performance across varying operating conditions and extended service intervals.

Industrial manufacturing operations utilize these stainless steel coils for producing heat exchangers, chemical processing equipment, precision machinery components, and specialized tooling applications. The thermal stability and chemical inertness make these materials ideal for environments involving temperature cycling, chemical exposure, and mechanical stress. Custom metal packaging manufacturer operations particularly value the combination of formability and corrosion resistance for creating durable packaging solutions that protect sensitive products during storage and transportation.

Quality Control & Compliance

Comprehensive quality management systems ensure that every coil of Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale meets international metallurgical standards and customer specifications. Advanced testing protocols encompass chemical composition analysis, mechanical property verification, surface quality assessment, and dimensional accuracy confirmation. These rigorous procedures guarantee consistent performance characteristics and eliminate variability that could compromise downstream manufacturing processes.

International certification compliance ensures compatibility with global supply chains and regulatory requirements across diverse markets. The manufacturing processes adhere to recognized quality standards that facilitate seamless integration into existing procurement and quality assurance programs. Comprehensive documentation accompanies each shipment, providing complete traceability and supporting quality audits throughout the supply chain.

Continuous process monitoring and statistical process control maintain tight tolerances on critical parameters including chemical composition, mechanical properties, and surface characteristics. Advanced metallurgical testing equipment enables real-time quality verification and immediate correction of any deviations from specification limits. This proactive approach ensures that customers receive materials that consistently meet or exceed their performance expectations.

Customization & Branding Options

Understanding that different applications require specific material characteristics, our Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale offers extensive customization capabilities to match precise customer requirements. Surface finish options extend beyond standard polishing to include specialized textures, patterns, and treatments that enhance both functional performance and aesthetic appeal. These custom surface treatments enable manufacturers to differentiate their products while maintaining the underlying corrosion resistance and mechanical properties.

Dimensional customization encompasses thickness variations, width specifications, and coil configurations optimized for specific manufacturing processes and equipment capabilities. Advanced slitting and cutting operations ensure precise dimensional control while maintaining edge quality essential for subsequent forming operations. Custom packaging configurations accommodate various handling systems and storage requirements, optimizing logistics efficiency and material protection during transportation.

OEM tin packaging solutions benefit from our ability to provide material specifications tailored to specific forming requirements and performance criteria. Collaborative engineering support helps customers optimize material selection and processing parameters to achieve desired performance characteristics while minimizing costs. This partnership approach ensures that the final product meets both functional requirements and commercial objectives.

Packaging & Logistics Support

Professional packaging solutions protect the integrity of Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale throughout global distribution networks. Advanced protective materials and packaging configurations prevent surface damage, contamination, and corrosion during extended transportation and storage periods. Moisture barriers, protective films, and cushioning materials ensure that materials arrive in pristine condition ready for immediate processing.

Logistics optimization encompasses coil configuration, packaging dimensions, and handling requirements designed to maximize shipping efficiency and minimize transportation costs. Standardized packaging formats facilitate automated handling while custom configurations accommodate specific equipment limitations and facility constraints. Comprehensive labeling and documentation systems support efficient inventory management and quality traceability throughout the supply chain.

International shipping expertise ensures compliance with export regulations, documentation requirements, and customs procedures across diverse global markets. Professional logistics coordination minimizes transit times and reduces the risk of delays or complications during international transportation. This comprehensive support enables customers to focus on their core manufacturing operations while ensuring reliable material supply.

Why Choose Us

Our commitment to excellence in stainless steel manufacturing spans decades of experience serving international markets across diverse industrial sectors. This extensive background has enabled us to develop sophisticated manufacturing processes and quality control systems that consistently deliver superior products meeting the most demanding specifications. Our global presence and established distribution networks ensure reliable supply chain support for customers worldwide, regardless of their geographic location or market requirements.

As a recognized metal packaging supplier, we understand the critical importance of material consistency and performance reliability in maintaining production schedules and product quality. Our comprehensive technical support capabilities extend beyond simple material supply to include application engineering, process optimization, and troubleshooting assistance that helps customers maximize the value of their material investments. This collaborative approach has established long-term partnerships with leading manufacturers across multiple industries.

Continuous investment in advanced manufacturing technology and process improvement ensures that our Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale remains at the forefront of metallurgical excellence. Our research and development capabilities enable rapid response to evolving market requirements and emerging application challenges. This forward-thinking approach positions our customers for success in increasingly competitive global markets.

The combination of technical expertise, manufacturing capability, and customer service excellence makes us the preferred choice for distributors, manufacturers, and processors requiring premium stainless steel materials. Our commitment to sustainable manufacturing practices and environmental responsibility aligns with the growing emphasis on corporate sustainability initiatives while maintaining the performance standards essential for industrial applications.

Conclusion

Factory Hot-rolled Stainless Steel Coil Grades 201/304/316, Custom Cold-rolled 0.5mm - 12mm Polished Wholesale represents the optimal solution for manufacturers and distributors seeking premium stainless steel materials that deliver consistent performance across demanding applications. The comprehensive grade selection, precise dimensional control, and superior surface quality combine to provide exceptional value for operations requiring reliable material characteristics and predictable processing behavior. Whether supporting architectural projects, food processing operations, automotive manufacturing, or specialized industrial applications, these versatile stainless steel coils provide the foundation for successful manufacturing outcomes while meeting the stringent quality standards expected in today's competitive global marketplace.